|

|

|

|

|

|

| Cellulose nanofibers can help particles in ink and printed electronics disperse evenly, rather than spread apart like dried coffee rings. |

TSUKUBA, Japan, May 10, 2017 - (ACN Newswire) - Drying is an important part of printing words and electronics. Particles suspended in liquid are applied to a surface and the liquid evaporates leaving the particles behind. Many times, the particles dry unevenly because of the so-called 'coffee ring effect'. Much like when spilled coffee dries up and leaves behind a hollow ring, particles tend to move to the outside of the liquid droplet. This is a problem, particularly for printed electronics, which require uniform application of a liquid for maximum performance.

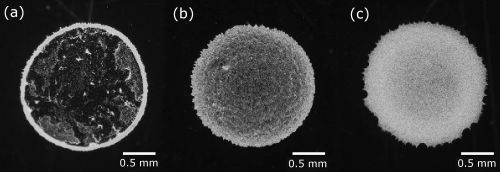

| | Photographs of dried colloidal mixtures of polystyrene particles (diameter 1.4 um) and cellulose fibers (diameter ca. 20 nm, length ca. 1 um).

The polystyrene concentration is fixed at 0.1 wt%, and that of cellulose is 0 (a), 0.01 (b) and 0.1 wt% (c). |

Cellulose nanofibers offer an environmentally friendly and effective solution to this problem, explain researchers from Japan in a paper recently published in Science and Technology of Advanced Materials.

The researchers tested three different concentrations of cellulose nanofibers added to a solution with suspended particles. They also tried increasing the particle concentration in a solution with no added nanofibers. They photographed the drying process under a microscope over time.

The solutions with nanofibers dried much more evenly than those without. Instead of a hollow ring, the particles condensed into a solid dot, slightly shrinking in size as the liquid evaporated. Particles in the mixtures with nanofibers also moved at a consistent pace. There was no final rush to the periphery as was observed in the solutions without nanofibers.

The researchers conclude that cellulose nanofibers can improve the drying process and avoid problems stemming from uneven drying, such as degradation of paint coatings, clarity of printed characters on paper, and conductivity of printed electronics.

Once the solution dries, the nanofibers are left behind along with the desired particles. How the nanofibers impede or benefit material performance is a topic for further research.

"The addition of cellulose nanofibers may alter the electrical resistivity of conductive wires in the printed electronics, but the fine tuning of the concentration might be exploited for the control of electric resistivity itself," write the research team from Tokyo University of Agriculture and Technology, and Nagoya University.

Article information:

Yuto Ooi, Itsuo Hanasaki, Daiki Mizumura and Yu Matsuda

"Suppressing coffee-ring effect of colloidal droplet by dispersed cellulose nanofibers"

Science and Technology of Advanced Materials, 2017, 18:1, 316-324.

http://dx.doi.org/10.1080/14686996.2017.1314776

For further information please contact:

Itsuo Hanasaki,

Institute of Engineering,

Tokyo University of Agriculture and Technology,

Naka-cho 2-24-16, Koganei-shi, Tokyo 184-8588 Japan

hanasaki@cc.tuat.ac.jp

Journal information

Science and Technology of Advanced Materials (STAM), http://www.tandfonline.com/stam is an international open access journal in materials science. The journal covers a broad spectrum of topics, including synthesis, processing, theoretical analysis and experimental characterization of materials. Emphasis is placed on the interdisciplinary nature of materials science and on issues at the forefront of the field, such as energy and environmental issues, as well as medical and bioengineering applications.

For more information about STAM please contact

Mikiko Tanifuji

Publishing Director

Science and Technology of Advanced Materials

E-mail: TANIFUJI.Mikiko@nims.go.jp

Press release distributed by ResearchSEA for Science and Technology of Advanced Materials.

Topic: Research and development

Source: Science and Technology of Advanced Materials

Sectors: Electronics, Science & Nanotech

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2024 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| Science and Technology of Advanced Materials |

| Apr 17, 2024 22:00 HKT/SGT |

|

A new spin on materials analysis |

| Apr 12, 2024 18:00 HKT/SGT |

|

Kirigami hydrogels rise from cellulose film |

| Feb 27, 2024 08:00 HKT/SGT |

|

Sensing structure without touching |

| Nov 21, 2023 07:00 HKT/SGT |

|

Nano-sized probes reveal how cellular structure responds to pressure |

| Nov 17, 2023 10:00 HKT/SGT |

|

Machine learning techniques improve X-ray materials analysis |

| Nov 14, 2023 20:00 HKT/SGT |

|

A bio-inspired twist on robotic handling |

| Oct 17, 2023 08:00 HKT/SGT |

|

GPT-4 artificial intelligence shows some competence in chemistry |

| Aug 24, 2023 09:00 HKT/SGT |

|

Closing the loop between artificial intelligence and robotic experiments |

| May 24, 2023 09:00 HKT/SGT |

|

Machine intelligence for designing molecules and reaction pathways |

| May 13, 2023 00:00 HKT/SGT |

|

Face-down: Gravity's effects on cell movement |

| More news >> |

|

|

|