TOKYO, May 19, 2016 - (JCN Newswire) - Fujitsu Limited today announced that it has with Intel Corporation carried out a field trial to visualize manufacturing processes at Shimane Fujitsu Limited, which primarily manufactures notebook PCs. The field trial linked the FUJITSU Cloud Service IoT Platform with the Intel IoT Gateway. As a result of this trial, the companies were able to rationalize functionality testing and repair processes on Shimane Fujitsu's manufacturing line, and in line with this, cut additional shipping costs that resulted from delays by 30%. The trial was a part of the IoT collaboration with Intel, launched in May 2015.

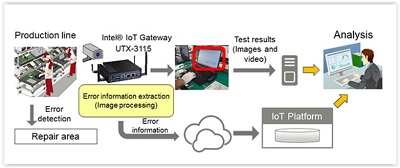

| | Operational trial at Shimane Fujitsu (Visualization of the functionality testing process) |

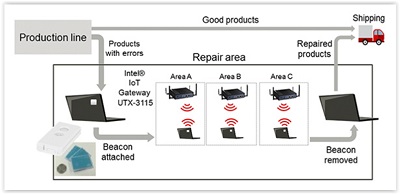

| | Field trial at Shimane Fujitsu (Visualization of the repair process) |

Going forward, Fujitsu will further strengthen its collaboration with Intel in the IoT field, creating new solutions and making them available to customers.

Background

In May 2015, Fujitsu and Intel reached an agreement to collaborate in building a more optimal systems environment by combining Fujitsu's cutting-edge technology with the Intel IoT Gateway, a blueprint for interoperable IoT solutions, with the aim of providing high-value IoT solutions. As a field trial of this collaboration, since May 2015 the companies have been working to improve manufacturing process efficiency through factory visualization at Shimane Fujitsu.

Summary of the Operational Trial

At Shimane Fujitsu, when products are detected to have faults in the functionality testing performed on the manufacturing line, they are sent to the repair area to receive a thorough diagnosis, analysis, and repair of the fault before being shipped, but there are sometimes cases in which the fault cannot be reproduced in the repair process. In these situations, it is necessary to conduct a comprehensive analysis of the work done by the worker involved in the functionality testing process who detected the fault, the tools used, and the status of the product being tested, in order to make clear the reason for the fault detection. Because real-time visualization of the task status of the functionality testing process was previously insufficient, however, it was impossible to identify the cause or implement policies to prevent reoccurrence, resulting in an excess of products being repaired.

In addition, in the repair process, information, such as the location of the product to be repaired in the repair line, whether or not it was held up, and each product's shipping deadline information, was not made visible in real time. This meant that it was not possible to separate out products that should be prioritized, causing them to miss planned shipping deadlines, often resulting in costs for arranging additional shipping trucks.

To visualize the functionality testing process, using Fujitsu Laboratories Ltd.'s image-processing technology that raises the recognition ratio for text in images, along with a framework that shortens the development of applications that use the technology, worker task status is recorded on video, along with the error code (a code that displays the content of the fault) displayed on the screen of the product to be repaired. This video is aggregated through the Intel IoT Gateway, for process visualization, by performing analytical image processing. As a result, in addition to improving the efficiency of error code aggregation, it is now possible to find trends in detected faults, and to efficiently analyze the circumstances when a fault was detected. By using the results of this analysis to limit misdetection of faults, Fujitsu will be able to reduce excess product repairs.

Next, for real-time visualization of the repair process, a beacon sensor is attached to each product needing repair that is sent to the repair line, which enables all line workers to grasp each product's location in the process, how long it has been there, and its shipping deadline. As a result, all employees can quickly understand the state of the entire process, leading them to independently prioritize the repair of products that have close shipping deadlines, or to help out in processes that are causing delays. This has reduced the number of additional shipping trucks required due to delays, leading to a 30% cut in shipping costs.

Future Developments

Fujitsu and Intel will use the experience gained at Shimane Fujitsu to establish IoT solutions for deployment to manufacturing customers. In addition, they will further accelerate the collaboration involving Fujitsu's IoT Platform and the Intel IoT Gateway by expanding IoT solutions to other fields, beginning with retail and the public sector.

Endorsement

Makiko Eda, President of Intel Japan K.K.

Intel has high expectations for the results of the joint field trial at Shimane Fujitsu. By implementing the Intel IoT Gateway, Fujitsu has improved the intelligence of its factory operations by using network connections to achieve manufacturing efficiencies. Intel will collaborate with Fujitsu and industry partners to accelerate transformations and increase the number of factories connected to smart networks that utilize IoT.

Contact:

Fujitsu Limited

Public and Investor Relations

Tel: +81-3-3215-5259

URL: www.fujitsu.com/global/news/contacts/

Fujitsu Laboratories Ltd.

ICT Systems Laboratories

Server Technologies Lab

E-mail: Retimer_ISSCC2015@ml.labs.fujitsu.com

Topic: Press release summary

Source: Fujitsu Ltd

Sectors: Electronics, Enterprise IT, IT Individual

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|