|

|

|

|

|

|

| Fabricating palladium-ruthenium nanoparticles could lead to improved industrial processes. |

TSUKUBA, Japan, Sept 22, 2016 - (ACN Newswire) - The chemical elements palladium (Pd) and ruthenium (Ru) are both used separately in the chemical industry. For a long time, researchers have thought that combining the two could lead to improved and novel properties for industrial applications. However, the two elements do not readily mix together to become a single material.

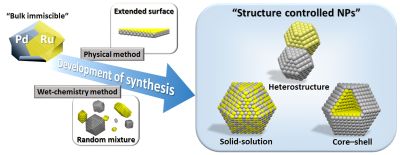

| | Synthesis of structure controlled bimetallic Pd-Ru nanoparticle alloys. (c)2016 Dongshuang Wu, Kohei Kusada, Hiroshi Kitagawa |

A study published in the journal Science and Technology of Advanced Materials reviewed the latest research into the fabrication of Pd-Ru bimetallic nanomaterials.

Early research from the past two decades showed that simply combining Pd and Ru nanoparticles led to a mixture with better properties for industrial catalytic purposes than either of the two elements alone. Since then, many groups have reported on Pd-Ru alloy nanoparticles. By varying the fabrication methods and compositions of Pd and Ru, Pd-Ru nanomaterials with different properties arise that can be suitable in industrial applications.

In 2010, Hiroshi Kitagawa from Japan's Kyoto University and colleagues fabricated a "solid-solution alloy" (involving the addition of the atoms of one element to the crystalline lattice of the other in a high-temperature reaction) from two neighbour elements of Pd in the periodic table, silver (Ag) and rhodium (Rh). The resultant material had attractive properties for industrial purposes, including the ability to absorb hydrogen. Rh is important in a variety of reactions in the automotive industry as well as industrial exhaust gas treatment. But it is scarce and expensive. The success of Ag-Rh led the team to speculate that, due to their similarities, combining Pd and Ru into solid-solution alloy nanoparticles might lead to a material with similar properties, providing a potential alternative to Rh.

In 2014, the team was the first to synthesize Pd-Ru solid-solution alloy nanoparticles. They found the Pd-Ru nanoparticles had higher catalytic activities compared to Ru or Pd nanoparticles. More recently, they found these nanoparticles were highly active in a catalytic process important for purifying harmful gases from exhaust gas - even outperforming Rh nanoparticles.

Further research is needed to understand how varying the size of bimetallic material affects its physical and chemical properties. For example, research has found that growing less than five ultrathin Pd films on Ru causes the resultant material to be inert to oxygen even though Pd itself is highly reactive to it. Theoretical modelling will also be important for predicting and explaining the properties of PdRu and other nanomaterials, the study concludes.

For further information please contact:

Dongshuang Wu, Kohei Kusada, Hiroshi Kitagawa*

Division of Chemistry, Graduate School of Science, Kyoto University,

Kitashirakawa, Oiwake-cho, Sakyo-ku, Kyoto 606-8502, Japan

*E-mail: kitagawa@kuchem.kyoto-u.ac.jp

Article information

"Recent progress in the structure control of Pd-Ru bimetallic nanomaterials", Dongshuang Wu, Kohei Kusada, Hiroshi Kitagawa, Science and Technology of Advanced Materials Vol. 17 (2016) p. 1221727

Published online: 19 Sep 2016

http://tandfonline.com/doi/full/10.1080/14686996.2016.1221727

Journal Information

Science and Technology of Advanced Materials (STAM) is the leading open access, international journal for outstanding research articles across all aspects of materials science. Our audience is the international materials community across the disciplines of materials science, physics, chemistry, biology as well as engineering. The journal covers a broad spectrum of materials science research including functional materials, synthesis and processing, theoretical analyses, characterization and properties of materials. Emphasis is placed on the interdisciplinary nature of materials science and issues at the forefront of the field, such as energy and environmental issues, as well as medical and bioengineering applications.

http://tandfonline.com/loi/tsta20#.VrgX82fotYU

For more information about the journal Science and Technology of Advanced Materials, contact:

Mikiko Tanifuji

Publishing Director

Science and Technology of Advanced Materials

Email: TANIFUJI.Mikiko@nims.go.jp

Press release distributed by ResearchSEA for Science and Technology of Advanced Materials.

Topic: Research and development

Source: Science and Technology of Advanced Materials

Sectors: Chemicals, Spec.Chem, Materials & Nanotech, Science & Research

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| Science and Technology of Advanced Materials |

| July 8, 2025 06:48 HKT/SGT |

|

Progress towards potassium-ion batteries |

| June 23, 2025 00:15 HKT/SGT |

|

New method to blend functions for soft electronics |

| May 5, 2025 03:20 HKT/SGT |

|

New Database of Materials Accelerates Electronics Innovation |

| Jan 28, 2025 08:00 HKT/SGT |

|

High-brilliance radiation quickly finds the best composition for half-metal alloys |

| Dec 3, 2024 23:15 HKT/SGT |

|

Machine learning used to optimise polymer production |

| Oct 25, 2024 23:00 HKT/SGT |

|

Machine learning can predict the mechanical properties of polymers |

| July 30, 2024 20:00 HKT/SGT |

|

Dual-action therapy shows promise against aggressive oral cancer |

| Apr 17, 2024 22:00 HKT/SGT |

|

A new spin on materials analysis |

| Apr 12, 2024 18:00 HKT/SGT |

|

Kirigami hydrogels rise from cellulose film |

| Feb 27, 2024 08:00 HKT/SGT |

|

Sensing structure without touching |

| More news >> |

|

|

|