|

|

|

|

|

|

| Combining Fuel Cell Technology with Micro Gas Turbines at Motomachi Plant |

Toyota City, Japan, Apr 26, 2017 - (JCN Newswire) - Toyota Motor Corporation has begun trial operations of the pressurized combined power generation system which has been installed at Motomachi Plant in Toyota City, Aichi Prefecture. The hybrid power generation system combines the use of solid oxide fuel cells (SOFC)(1) (hereafter, "fuel cells") and micro gas turbines(2). The trial operations will utilize the system as an internal power generation facility, with the aim of testing and evaluating the system's energy efficiency, performance, and durability.

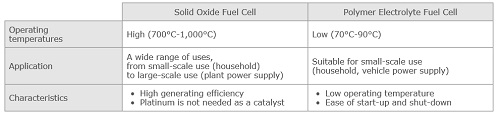

| | Reference: Difference between fuel cells |

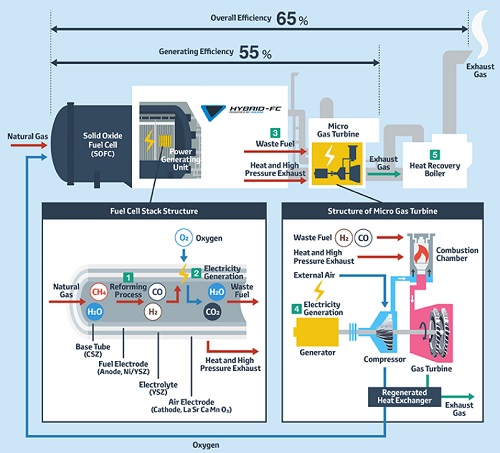

| | Overview of the hybrid power generation system |

The hybrid power generation system uses hydrogen and carbon monoxide which have been extracted by reforming natural gas, and employs fuel cell technology and micro gas turbine in its two-stage power generation mechanism, with a rated output of 250 kW. In addition, it has a cogeneration system (combined heat and power) that uses the waste heat produced in power generation.

This hybrid system achieves high generating efficiency (55%)(3) with its two-stage power generation system, and also increases overall efficiency (65%) by using the cogeneration system. For this reason, Toyota has positioned it as an effective technology that would help to realize the goal of achieving a low-carbon society. The electricity and waste heat generated is used within Motomachi Plant.

The newly introduced hybrid power generation system is being implemented as part of the "Technological Demonstration for targeting Mass-production of Pressurized Hybrid Power Generation System Consisting of Cylindrical Solid Oxide Fuel Cell (SOFC) and a Micro Gas Turbine (MGT)"(4) of the New Energy and Industrial Technology Development Organization (NEDO). This system was jointly developed by Toyota, Toyota's subsidiary, Toyota Turbine and Systems Inc., as well as Mitsubishi Hitachi Power Systems Ltd.

Toyota will continue to promote the development and introduction of the efficient utilization of hydrogen technology in plants, while continuously monitoring the results of the introduction and demonstration results of this hybrid power generation system. This represents a progress forward in terms of initiatives targeted at reaching zero CO2 emissions in plants, which is one aspect of the Toyota Environmental Challenge 2050 which had been announced in 2015.

Reference: Difference between fuel cells

http://www.acnnewswire.com/topimg/Low_ToyotaFuelCells.jpg

Overview of the hybrid power generation system

http://www.acnnewswire.com/topimg/Low_ToyotaHybridPower.jpg

1. Natural gas (CH4) is reformed within the fuel cell, and hydrogen (H2) and carbon monoxide (CO) are extracted.

2. Electricity is generated in the fuel cell through a chemical reaction that occurs between the hydrogen and carbon monoxide with the oxygen (O2) that is contained in the compressed air delivered by the micro gas turbine. .

3. Waste fuel that is unused in fueled power generation (H2 and CO) is delivered to the micro gas turbines together with the heat and high pressure exhaust that is produced during power generation. .

4. The waste fuel is burned in the micro gas turbines, and electricity is generated as it rotates. . 5Waste heat is collected from the exhaust gas produced during the burning process.

(1) Solid oxide fuel cells use ion conductive ceramic as an electrolyte, allowing for operating temperatures between 700degC-1,000degC.

(2) A very small sized gas turbine with a small power output.

(3) Equivalent to the amount of electricity remaining after power used in the station (for operation of equipment used in power generation) is subtracted from the amount of power generated.

(4) In aiming to put SOFC into practical use for commercial and industrial use, NEDO provided subsidies for R&D and introduction of SOFC.

NEDO website http://www.nedo.go.jp/english/index.html

Contact:

Public Affairs Division

Global Communications Department

Toyota Motor Corporation

Tel: +81-3-3817-9926

Topic: Press release summary

Source: Toyota Motor Corporation

Sectors: Automotive

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2025 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|