|

|

|

|

|

|

| Provides improved quality and increased efficiency through smooth coordination of design information with manufacturing departments |

TOKYO, July 7, 2017 - (JCN Newswire) - Fujitsu today announced the launch of iCAD SX V7L6, the latest version of the Fujitsu Manufacturing Industry Solution iCAD SX, its 3D CAD software for industrial machinery design, incorporating a proprietary 3D CAD engine, the world's fastest, which can process one million components in 0.2 seconds.

| | iCAD SX V7L6 summary |

| | Pricing and Availability |

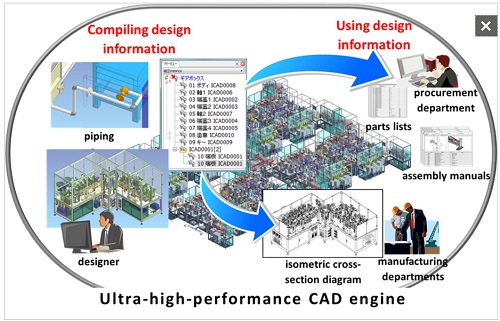

With iCAD SX V7L6, it is now possible to record component information, including component number and assembly sequences, to the 3D data for each component, from the initial stages of design. Use of this compiled information makes it easier for users to create assembly manuals and parts lists, and to coordinate information with manufacturing departments. In addition, new functionality has been added, such as the ability to create isometric cross-section diagrams(1), reducing the number of man-hours needed to create diagrams.

With these capabilities, this software improves the quality of machinery and equipment design and improves the efficiency of the processes through to manufacturing.

Background

In the machinery and equipment industry, it has become important to improve development capabilities for increasingly complex products and to speed up entry into the market in order to increase market competitiveness. For this reason, it has become urgently necessary for industrial machinery manufacturers to improve design quality and reduce design man-hours.

In addition, increased efficiency through 3D design has become more common in design departments, but manufacturing departments still require multiple 2D blueprints, meaning that the gains in reduced man-hours have not been realized across the whole design process.

In a move to resolve these issues, Fujitsu is offering iCAD SX V7L6, with enhanced diagram creation functionality and functionality for compiling and using design information.

http://www.acnnewswire.com/topimg/Low_FujitsuiCad7717.jpg

iCAD SX V7L6 Summary

Features of iCAD SX V7L6

1. Delivers higher product quality and improved efficiency in purchasing and manufacturing processes by compiling and using design information within 3D data

This version of the software offers enhanced functionality for compiling and using design information, able to record within the 3D data not only component material, weight, and price information, which could already be recorded, but also component configuration information and part numbers, as well as assembly-sequence information, taking into account later processes (such as component procurement and manufacturing). This means that it is easy to create things like assembly manuals and parts lists from the recorded design information. In addition, because the information can be used as is in later processes, this software improves product quality and work efficiency.

2. Higher diagram-creation efficiency with isometric cross-section diagram creation functionality

With this product, Fujitsu has incorporated new functionality enabling easy creation of isometric cross-section diagrams. This enables the detailed diagrams and cross-sections required in assembly diagrams to be displayed on one isometric cross-section diagram, reducing the number of man-hours required to create diagrams. In addition, this software reduces the man-hours required to create diagrams by about 40% by adding functionality that is needed in design departments, such as, in the creation of multi-view drawings(2), the ability to easily change whether components hidden in the rear should be shown with dotted lines or not shown, with settings for each component.

3. Further improvements in design efficiency through enhanced detailed design functionality

Ordinary machinery and equipment can include over ten thousand fastener components, such as nuts, bolts, and washers, and it is necessary to correctly design their positioning and combinations individually. With this product, the correct patterns for combining fastener components can be saved, and multiple components can be recognized as a single component, which increases the efficiency of positioning components and reduces mistakes in the combination of components.

In addition, welded components, which were previously recognized as separate components by the system, are now recognized as one component, with a function to create holes in all pieces at once. This not only makes designing holes in welded components more efficient, it also can prevent design omissions in the placement of holes.

Moreover, Fujitsu has enhanced the piping route design functionality in 3D. When designing the piping within a machine, it is necessary to consider a variety of factors, including interference with surrounding devices, length of piping, and number of turns. With this product, users can design piping while visually checking the positional relationship with surrounding devices on the screen, which improves product quality and work efficiency.

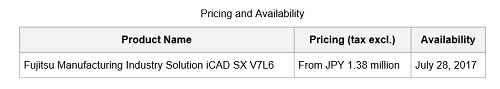

Pricing and Availability

http://www.acnnewswire.com/topimg/Low_FujitsuiCad7717Pricing.jpg

Sales Target

15,000 licenses in fiscal 2017 (Fujitsu's fiscal year ends March 31).

(1) Isometric cross-section diagram

A cross-section diagram looking at an object in a 3D model diagonally from above at an isometric angle (an angle where the three coordinate axes are equally foreshortened).

(2) Multi-view drawings

Diagrams showing an object from the three angles of front, side and top.

Contact:

Fujitsu Limited

Public and Investor Relations

Tel: +81-3-6252-2176

URL: www.fujitsu.com/global/news/contacts/

Topic: Press release summary

Source: Fujitsu Ltd

Sectors: Enterprise IT

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| Fujitsu Ltd |

| Mar 2, 2026 10:55 HKT/SGT |

|

Fujitsu supports sustainable growth for retailers with data and AI through Uvance for Retail |

| Feb 27, 2026 11:03 HKT/SGT |

|

Fujitsu POS solution enhances customer experience at Hankyu Hanshin Department Stores |

| Feb 25, 2026 11:00 HKT/SGT |

|

Beisia Automates Supermarket Refrigerator Temperature Monitoring and Recording with Fujitsu's IoT Visualization Solution |

| Feb 24, 2026 10:23 HKT/SGT |

|

Fujitsu expands Uvance for Finance offerings to accelerate DX across financial sector |

| Feb 19, 2026 11:12 HKT/SGT |

|

Osaka Hospital launches project to safely utilize generative AI for healthcare workforce improvements |

| Feb 18, 2026 09:41 HKT/SGT |

|

Fujitsu named to FORTUNE Magazine's list of 'World's Most Admired Companie's for eighth year running |

| Feb 17, 2026 11:21 HKT/SGT |

|

Fujitsu automates entire software development lifecycle with new AI-Driven Software Development Platform |

| Feb 13, 2026 21:50 HKT/SGT |

|

Fujitsu and 1Finity to highlight latest network technologies and AI solutions at MWC Barcelona 2026 |

| Feb 13, 2026 21:33 HKT/SGT |

|

Fujitsu to present latest technologies for creating social and industrial value through fusion of AI and computing at India AI Impact Summit 2026 |

| Feb 12, 2026 18:59 HKT/SGT |

|

Lockheed Martin and Fujitsu Formalize Industrial Collaboration for Japan Defense |

| More news >> |

|

|

|

|