|

|

|

|

|

|

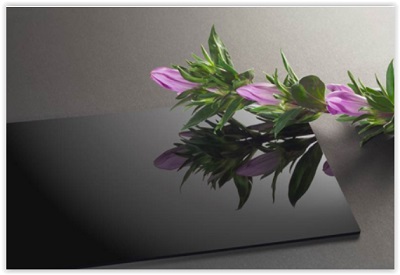

| - Cutting edge, environmentally friendly and exquisite material - |

TOKYO, Aug 17, 2016 - (JCN Newswire) - NEC Corporation (NEC; TSE: 6701), in collaboration with the Kyoto Institute of Technology and a representative Japanese lacquerware artist, Dr. Yutaro Shimode, announced today the development of a bioplastic using resin (cellulose resin(1)) from grasses, trees and other non-edible plant resources that features the highly regarded "Urushi black" color of Japanese traditional lacquerware(2).

| | Cutting edge, environmentally friendly and exquisite material |

In order to create the new cellulose-based bioplastic, NEC developed a unique technology for mixing additives to adjust coloration and light reflectance of the material, enabling, for the first time, the realization of optical properties (low brightness, high glossiness, etc.) similar to the deep and shiny "Urushi black" color of high-grade Japanese lacquerware. The new plastic balances a high level of environmental friendliness and decorativeness and makes it possible to mass produce products of various shapes and patterns using the usual molding process for ordinary plastics.

"In response to the depletion of resources and food shortage problems, the need for non-edible-plant-based plastics is increasing. In addition to NEC's history in the development of a unique cellulose-based plastic (NeCycle(R)(3)) using non-edible plant materials for use in durable electronic products, we have now developed a new bioplastic that, in addition to high functionality, realizes the decorativeness of Japanese lacquerware, which is highly evaluated throughout the world, and illustrates a beauty well beyond what petroleum-based plastics can provide," said Dr. Masatoshi Iji, Research Fellow, IoT Devices Research Laboratories NEC Corporation.

This development was carried out in collaboration with the Kyoto Institute of Technology's Future-Applied Conventional Technology Centre, which is known for its outstanding achievements in future-applied conventional technology research (scientific analysis of traditional crafts and their applications in advanced material science), and Dr. Yutaro Shimode(4), a prominent Japanese lacquerware artist.

The development process involved, first, the fabrication by Dr. Shimode of a Japanese lacquerware "Urushi craft" model (transparent resin plate repeatedly coated with Japanese lacquer and polished by hand) that served as the standard for the advanced optical properties exhibited by high-quality Japanese lacquerware. Scientific analysis was performed on Japanese lacquerware at the Kyoto Institute of Technology. Based on the results, NEC then developed an optimized technology for modifying and mixing of the additives.

Going forward, NEC will pursue business partnerships aimed at commercializing the new bioplastic in durable products and high-grade materials that require a high level of decorativeness, such as the interior components of luxury cars.

Key features of the "Urushi black" bioplastic

1. Use of non-edible plant materials that are readily available as the main ingredient

The new bioplastic uses cellulose resin produced from cellulose that is widely available from non-edible plant resources, such as grasses, the stalks of cereal crops and wood, and has the potential to be used as a substitute for petroleum.

2. Realizes the advanced optical properties (Urushi black) of high-grade Japanese lacquerware

Black coloring agents and highly refractive organic ingredients were mixed with the above cellulose resin as special additives to adjust the resin's coloration and light reflectance properties. By dispersing the additives into fine particles, NEC became the first to achieve the advanced optical properties exhibited by high-grade Japanese lacquerware. The new bioplastic was able to exhibit the deep and shiny "Urushi black" color characteristic of Japanese lacquerware, at a quality similar to the high-grade "Urushi craft" model fabricated by Dr. Yutaro Shimode, a leading lacquerware artist in Japan

3. The new bioplastic can be mass-produced into products of various shapes using the molding process for ordinary plastics

Conventionally, lacquerware is produced by coating the surface of substrates with lacquer and polishing them. For this newly developed bioplastic, the materials can be heated, melted, and injected into molds (mirror-finishing) to form shapes (injection molding), as with ordinary plastics. This makes it possible to mass-produce the bioplastic into products of various shapes and patterns.

NEC is scheduled to present this technology at the 24th Material Processing Technical Conference (M&P 2016) to be held at Waseda University in Tokyo from November 25 to 26, 2016.

(1) Cellulose resin: Resin made using cellulose that is the main ingredient of the stems of cereal crops and wood, and is not suitable for human consumption.

(2) Lacquerware: Conventionally, Japanese lacquerware is made by substrate processing of the surface of wood products, manual coating with lacquer (a mixture of natural lacquer substance and coloring agents), and letting the lacquer harden, followed by repeated polishing of the product. Since manufacturing involves a tedious process, mass production as an industrial product has not been possible.

(3) NeCycle(R): Brand name of bioplastic material developed mainly by NEC.

(4) Japanese lacquerware artist, Dr. Yutaro Shimode: a third-generation president of Shimode makie-studio who is a leading lacquerware artist in Japan. He is a professor at the Faculty of Cultural Studies of Kyoto Sangyo University. His recent international engagements include being invited by the Ministry of Foreign Affairs of Japan to hold lectures and exhibits at famous museums in Europe.

(Ministry of Foreign Affairs website:http://www.mofa.go.jp/mofaj/files/000158375.pdf)

Contact:

NEC

Seiichiro Toda

s-toda@cj.jp.nec.com

+81-3-3798-6511

Topic: Press release summary

Source: NEC Corporation

Sectors: Materials & Nanotech, Speciality Chemicals

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| NEC Corporation |

| Feb 25, 2026 17:00 HKT/SGT |

|

NEC Implements AI Code Review Service "Metabob," Reducing Technical Verification Time by Up to 66% |

| Feb 9, 2026 20:18 HKT/SGT |

|

NEC Exhibits at MWC Barcelona 2026, the World's Largest Mobile-Related Exhibition |

| Jan 28, 2026 09:05 HKT/SGT |

|

NEC Develops High-Efficiency, Compact Power Amplifier Module for 5G Base Station Radio Units |

| Jan 23, 2026 14:00 HKT/SGT |

|

NEC Develops New 5G Base Station Radio Unit for Enhanced Communication Throughput, Compactness, and Energy Efficiency |

| Jan 15, 2026 16:00 HKT/SGT |

|

NEC Launches "NEC Composable Disaggregated Infrastructure Solution" for Distributed Computing Resources |

| Dec 19, 2025 02:06 HKT/SGT |

|

NEC and emaratech Collaborate on Biometric Smart Gates Supporting UAE Airport Operations |

| Dec 15, 2025 18:41 HKT/SGT |

|

NEC Provides Vehicle Management Equipment for Autonomous Driving at Tokyo International Airport |

| Dec 15, 2025 18:04 HKT/SGT |

|

NEC and AEROTHAI Elevate Air Traffic Safety with Advanced Time Sync Solutions from Adtran Oscilloquartz |

| Dec 12, 2025 18:59 HKT/SGT |

|

Bank Mandiri Enhances Digital Resiliency for Financial Trading in Indonesia through Advanced Time Sync Solutions with NEC and Adtran Oscilloquartz |

| Dec 12, 2025 17:13 HKT/SGT |

|

NEC and ClimateAi sign a Memorandum of Understanding (MoU) for business co-creation to enhance climate resilience across various industries |

| More news >> |

|

|

|

|