|

|

|

|

|

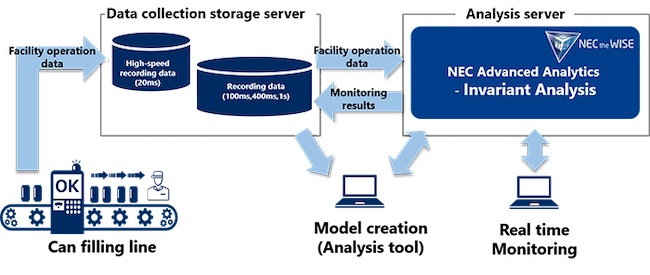

TOKYO, Feb 18, 2022 - (JCN Newswire) - NEC Corporation (TSE: 6701) announced today that it will provide Suntory Beer, Inc. with NEC Advanced Analytics-Invariant Analysis, an AI-based facility anomaly detection system. This system is planned to begin operation in late May at the can filling line at Suntory's Natural Water Beer Plant in Kyoto, Japan. The project is being promoted in collaboration with Suntory System Technology Co., Ltd., which is responsible for the Suntory Group's IT technologies, and activities are being conducted with an eye to expanding the project to each Suntory Group company.

| | System Configuration Overview |

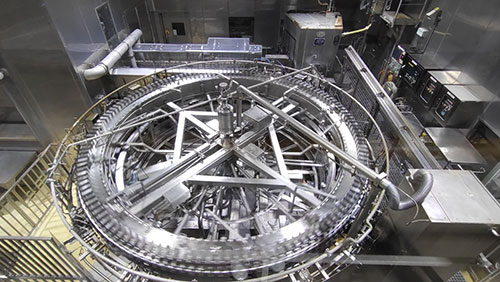

| | Filling machine |

Traditionally, at production lines at manufacturing sites where mass production is undertaken, field personnel mainly use sensor data from equipment to monitor usage thresholds. However, there is a need for experience and know-how in order to understand the fine changes in individual data, and passing these skills along is a challenge.

This new anomaly detection system is centered on NEC Advanced Analytics-Invariant Analysis, which uses Invariant Analysis Technology, part of NEC's leading-edge AI technology group, NEC the WISE. By collecting and analyzing a large amount of time-series data from a large number of sensors installed in facilities through control systems such as PLCs (Programmable Logic Controller), modeling invariant relationships between sensors (invariants) and comparing changes between predicted data with actual data, users can detect "irregular" occurrences at an early stage. This system takes advantage of the features of White Box AI and provides information necessary for taking action at maintenance sites, such as where and why functions are performing abnormally. When modeling, users can easily visualize conditions by simply entering the sensor information they want to see with the time that those sensors were operating.

A new can filling line using IoT will be started in April at Suntory's Natural Water Beer Plant in Kyoto in order to accelerate DX in production lines. In this line, NEC's system will automatically discover the relationships between approximately 1,500 sensors, and issue alarms when changes occur, thereby detecting equipment anomalies at an early stage and helping to resolve them as soon as possible.

Moreover, NEC will install microphones near filling machines in order to analyze when sounds are different from usual, which could possibly indicate an abnormality with the system.

In the future, it is expected that these advancements could help to reduce the number of people required for maintenance work, while helping to detect abnormalities more quickly.

"Through the provision of this system, NEC is supporting the stable operation of facilities, preserving expert know-how and experience, recognizing errors that are difficult to detect, and contributing to the DX of production lines," said Masayuki Ikeda, General Manager, AI Analytics Division, NEC Corporation.

About NEC Corporation

NEC Corporation has established itself as a leader in the integration of IT and network technologies while promoting the brand statement of "Orchestrating a brighter world." NEC enables businesses and communities to adapt to rapid changes taking place in both society and the market as it provides for the social values of safety, security, fairness and efficiency to promote a more sustainable world where everyone has the chance to reach their full potential. For more information, visit NEC at https://www.nec.com.

Topic: Press release summary

Source: NEC Corporation

Sectors: Enterprise IT, Artificial Intel [AI]

http://www.acnnewswire.com

From the Asia Corporate News Network

Copyright © 2026 ACN Newswire. All rights reserved. A division of Asia Corporate News Network.

|

|

|

|

|

|

|

| NEC Corporation |

| Feb 25, 2026 17:00 HKT/SGT |

|

NEC Implements AI Code Review Service "Metabob," Reducing Technical Verification Time by Up to 66% |

| Feb 9, 2026 20:18 HKT/SGT |

|

NEC Exhibits at MWC Barcelona 2026, the World's Largest Mobile-Related Exhibition |

| Jan 28, 2026 09:05 HKT/SGT |

|

NEC Develops High-Efficiency, Compact Power Amplifier Module for 5G Base Station Radio Units |

| Jan 23, 2026 14:00 HKT/SGT |

|

NEC Develops New 5G Base Station Radio Unit for Enhanced Communication Throughput, Compactness, and Energy Efficiency |

| Jan 15, 2026 16:00 HKT/SGT |

|

NEC Launches "NEC Composable Disaggregated Infrastructure Solution" for Distributed Computing Resources |

| Dec 19, 2025 02:06 HKT/SGT |

|

NEC and emaratech Collaborate on Biometric Smart Gates Supporting UAE Airport Operations |

| Dec 15, 2025 18:41 HKT/SGT |

|

NEC Provides Vehicle Management Equipment for Autonomous Driving at Tokyo International Airport |

| Dec 15, 2025 18:04 HKT/SGT |

|

NEC and AEROTHAI Elevate Air Traffic Safety with Advanced Time Sync Solutions from Adtran Oscilloquartz |

| Dec 12, 2025 18:59 HKT/SGT |

|

Bank Mandiri Enhances Digital Resiliency for Financial Trading in Indonesia through Advanced Time Sync Solutions with NEC and Adtran Oscilloquartz |

| Dec 12, 2025 17:13 HKT/SGT |

|

NEC and ClimateAi sign a Memorandum of Understanding (MoU) for business co-creation to enhance climate resilience across various industries |

| More news >> |

|

|

|

|